Precision made in Germany. As per DIN 8606. The heart of a system, versatile and expandable.

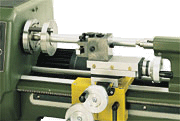

Precision lathe PD 400/CNC

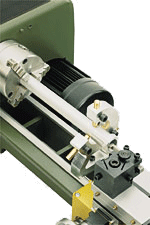

Z-axis and X-axis with recirculating ball spindles and two powerful step motors.

Control unit for connecting to PC or laptop with activation of the main spindle and the step motors.

Including user-friendly and WINDOWS® compatible software (see description below).

NO 24 500

CNC control of Z-axis and X-axis enables precise turning, facing and longitudinal turning of steel and non-ferrous metal.

Axes drive with powerful step motors and recirculating ball spindles (no backlash). For facing and longitudinal turning, for turning balls, radii and any freely formed contours made of steel and non-ferrous metal. Work piece machining is effected automatically by software and can be reproduced as often as required.

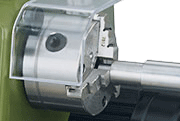

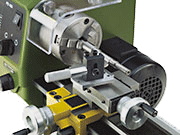

Otherwise the mechanical design is almost identical to the proven PROXXON lathe PD 400: Solid, cross-braced cast iron bed with ground and wide legged prism guide for apron and tailstock ensure vibration-free working and optimum precision. High quality 3-jaw lathe chuck (Ø 100mm). 6 spindle speeds (80 – 2,800/min) are provided via belt drive. Including rotating centre MK 2 and tailstock chuck. With quick-change tool post with 2 holders (with stop and height adjustability).

Complete with recirculating ball spindles, powerful step motors and the required limit switches, the CNC control unit, all necessary connecting cables and WINDOWS® compatible software on CD-ROM.

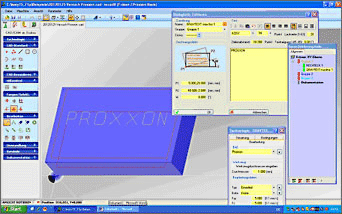

PROXXON CAD/CAM software for WINDOWS®

Brief description of software and hardware:

The software is harmonized with mechanics, motors and the control unit of the CNC machine, thus offering the optimum performance.

The CNC control unit controls the step motors of the machine. The PC software provides the machine with the geometry information for travel of the tools (via RS 232 interface). This means that the control unit is the interface between software and the mechanics of the machine.

Powerful micro processors and accordingly dimensioned step motors and phases ensure that the motors always provide enough power for any machining processes. Two freely usable output relays in the casing of the control unit provide facilities for control of additional functions, e.g. a working lamp. Including connection cables with suitable plugs and built-in power supply for connection to 220 – 240V.

Simple creation of work piece geometry

The CAD window is displayed when the programme starts. The work piece contour is created in the familiar WINDOWS® environment. Numerous auxiliary aids help during programme operation, which supports both coordinate entry (absolute and relative) in addition to mouse use.

Technology information is allocated to every drawing element. This makes, for example, different processing speeds and manual tool replacement possible.

Read-in of existing files in .dxf format is possible as well.

Automatic generation of CAM data

The finished drawing of the tool is converted, by a mouse click, into the instruction set for the machine. So, machining can be started immediately. The instruction set generated in this way is in accordance with DIN/ISO 66025 and can be manually edited and exported. Conversely, the system also permits importing or complete self writing of data sets.

Technical Data

| Power supply | 220 – 240V / 50/60Hz |

| Drive | Condenser motor with 550W |

| X-axis Spindle drive | Recirculating ball spindle with 2.0mm inclination, flank diameter 8mm. Step motor with 1.8A and 50Ncm dwell moment; travel distance: approx. 70mm |

| Z-axis Spindle drive | Recirculating ball spindle with 4.0mm inclination, flank diameter 12mm. Step motor with 1.8A und 50Ncm dwell moment; travel distance: approx. 300mm |

| 6 spindle revolutions | 80 – 160 – 330 – 660 – 1,400 – 2,800/min . Selectable with switch (two-stage) and by placing drive belt. |

| Control of step motors | via CNC control unit (included in scope of delivery) |

| Software | on CD-ROM, installation under Windows 98, Windows 2000, Windows XP, Windows Vista, Windows 7 and Windows 10 |

| Drive connection | via RS 232 interface (or: use of a USB adapter), connecting cables to PC included in scope of delivery |

| Sizes | Machine: L 900 x W 400 x H 300mm . Control unit: L 450 x W 270 x H 60mm |

| Total weight | Machine: approx. 45kg / Control unit: approx. 4kg |

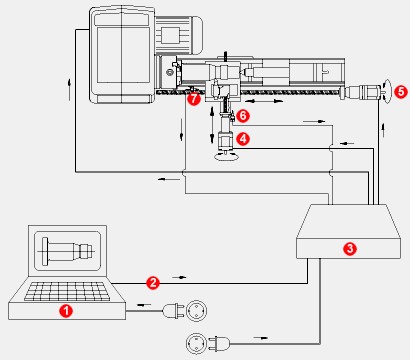

Connection system

[1] Computer with software

[2] RS 232 interface

[3] MCS-multicontroller

[4] Step motor (X-axis)

[5] Step motor (Z-axis)

[6] Switch X-axis

[7] Switch Z-axis

NO 24 506 Thread cutting device for the lathe PD 400/CNC

A complete attachment kit with rotary encoder for the main spindle, belt pulleys, synchronous belts and all required accessory parts.

The software of the PD 400/CNC has already been programmed accordingly: Available now are the standard male threads M 1 to M 42. Special threads of any type (e.g. inch threads) can be manufactured as well with different pitches and thread depths. Including detailed assembly instructions.

Accessories for the PD400

NO 24 402 Splash guard and chip collecting tray for lathe PD 400

Made from 1.5mm steel plate, powder coated. A welded cover protects the motor. Mounting holes and raised base to secure the lathe are pre-drilled. Seeping through of coolant is impossible. Length 800 x width 270 x height 290mm.

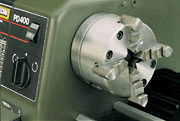

NO 24 407 Self-centering 3-jaw chuck

Identical to the lathe chuck of lathe PD 400. Capacity through reversing chucks 3 – 100mm.

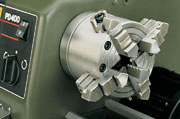

NO 24 408 Self-centering 4-jaw chuck

The jaws are not independently adjustable, i.e. they are self-centering. High accuracy. Chuck diameter 100mm.

Five piece set NO 24 550

One each roughing out, parting, finishing cut, left and right cutter. Comes in wooden box with sliding lid. 10 x 10 x 80mm.

Three piece thread cutting set NO 24 552

One cutter for external thread , one for internal thread (both ground to 60°, metric), one general cutting . Supplied in wooden box with sliding lid. 10 x 10 x 80mm.

Cutter set with tungsten inserts NO 24 556

Three holders (90mm long):

for roughing out;

for longitudinal work;

for 90mm boring bar, holes from 12mm.

Standard tungsten inserts, 55°, plated (commercially available version). Three additional inserts securing screw and key TX 8 are included. 10 x 10mm.

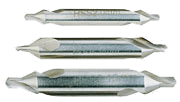

Three piece centre drill set NO 24 630

Made of HSS steel. DIN 333 (type A) 60°. Complete set centre drills with sizes of 2 – 2.5 and 3.15mm.

NO 24 410 4 jaw chuck with independent jaws

Used to mount irregularly and asymmetrically shaped objects. Each jaw is adjusted individually and centering is thus achieved manually. Hardened, reversible jaws. Chuck diameter 100mm..

NO 24 412 Faceplate and clamps

Is fitted instead of the standard chuck. Ideal for clamping larger and asymmetrically shaped work pieces. Ø 125 mm. 2 continuous T-slots. With clamping jaws.

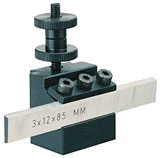

NO 24 417 Parting tool holder and tool

Used in the PD 400 quickchange system. Used to part stock and cut slots. The 12 x 3 x 85mm HSS tool contains cobalt.

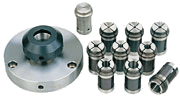

Collet attachment with collets for PD 400 NO 24 419

For accurate use on round components. One hardened collet each hardened collet 2 – 3 – 4 – 5 – 6 – 8 – 10 – 12 and 14mm are included. Concentric accuracy better than 0.02mm, much better than a chuck. One soft collet for making a custom size yourself. The included collet attachment is mounted in the place of the headstock chuck. Supplied in a wooden box.

Tool holder for rotary tools NO 24 098

For use on lathe machines.

Made of steel with standard 20mm MICROMOT collar size. For precise clamping of rotary tool IBS/E or LBS/E in the tool post of the lathe. Shaft 8 x 10mm. Total length 65mm.

14-piece parallel supports set NO 24 266

Ground in pairs. For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 – 62 HRC). Parallel accuracy 0.02mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

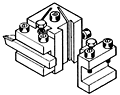

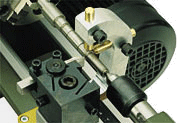

Tool post NO 24 415

Including two holders. Provides quick tool changes with easy height adjustment. For turning tools 10 x 10mm.

Individual quick-change holder NO 24 416

Fits the tool post of PD 400.

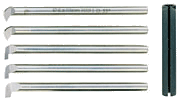

NO 24 520 HSS boring tool set, 6 pieces

One each cutter for 60 degree (metric) and 55 degree (Whitworth) inside threads, 1.3mm – 2.65mm and 4mm. Shaft of Ø 6mm. Length 95mm. The cutters are held by a tool holder (9 x 9mm) that mounts to the tool post of either PD 230/E, PD 250/E or PD 400. Comes in wooden box with sliding lid..

NO 24 414 Centre turning accessory for PD 400

Ideal when turning with highest possible accuracy. Supplied with 2 dead centres (MK2 and MK3), drive/ face plate with 30mm bore as well as reducing bushes 30/20mm and 30/15mm. A threaded drive pin screws into the headstock flange and the drive plate..

NO 24 404 Fixed steady to support longer pieces for PD 400

Used on the PD 400 when turning long, slender work pieces. Fitted directly to the bed-ways and is used when the tailstock support is inadequate. Maximum Ø 50mm.

NO 24 406 Travelling steady for PD 400.

Fitted to the carriage of the lathe. Indispensable when turning long, slender work pieces. Maximum Ø 50mm..

NO 24 062 Radius cutting attachment

Is mounted on the cross slide in place of the tool holder. For producing convex and concave shapes, for turning radii or 3/4 spheres with radii of 32mm max. Height adjustable tool holder (boring tool tip adjustable from 30 through 45mm above cross slide) for use with FD 150/E, PD 250/E, PD 400 and older PROXXON lathes. Dimensions: base plate 67 x 50mm, height 55mm. Including finishing cutter 8 x 8 x 80mm. In wooden box with sliding lid..

Die holder for round dies NO 24 082

For threads M 3 – 4 – 5 – 6 – 8 and 10. With holder Ø 10mm for mounting in the tailstock drill chuck of the lathe. The holder is held by hand while cutting the threads. Neatly packed in wooden box with sliding lid.